Rolex Oysterdate Precision 6694: A Collector’s Guide

The Rolex Oysterdate Precision 6694 offers the perfect starting point to step into the exciting world of Rolex. This timepiece carries a rich heritage dating

A Rolex watch movement’s accuracy is a big deal as it means that it surpasses the standards set by Switzerland’s official testing program. Your timepiece’s Rolex movement showcases decades of engineering excellence that collectors admire, yet few fully grasp.

Looking inside a Rolex movement reveals remarkable precision engineering. The iconic Caliber 3135, launched in 1988, became Rolex’s “workhorse” through its exceptional reliability and 48-hour power reserve. Rolex movements have challenged traditional boundaries consistently. The groundbreaking Caliber 620 in 1930 was the first automatic rotor that could wind in both directions. The modern Caliber 9001 stands as the most complex Rolex mechanism, featuring dual time zones and an annual calendar. The choice of movement depends on the specific model, yet all reflect Rolex’s steadfast dedication to excellence.

In this piece, you’ll find the hidden engineering marvels inside your Rolex automatic movement. The innovative components like Paraflex shock absorbers provide 50% more protection than traditional systems. These precision instruments undergo meticulous assembly and testing to surpass industry standards consistently.

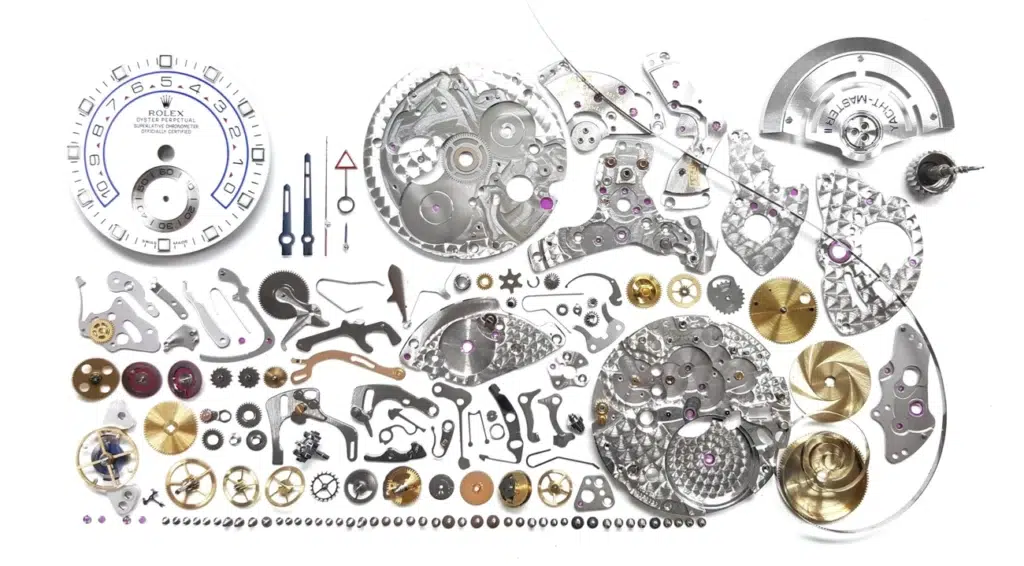

Image Source: Time+Tide Watches

A Rolex movement functions like a miniature city where precisely engineered parts work in perfect harmony. This mechanical marvel’s heart contains several critical components that power your timepiece with remarkable precision.

Every Rolex watch movement draws its power from the mainspring barrel. A tightly wound strip of special metal sits inside this cylindrical component and stores energy when you wind your watch. The mainspring’s gradual uncoiling releases energy through the gear train. This series of interconnected wheels transfers power and controls the rotation of the hour, minute, and second hands. The gear train converts the mainspring’s high torque into precise speeds needed for accurate timekeeping.

The escapement’s role involves regulating energy flow and stopping the mainspring from unwinding all at once. This sophisticated mechanism creates the distinctive “tick-tock” sound as its components lock against each other 700,000 times daily. Rolex’s innovative Chronergy escapement boosts efficiency by 15% through its lightweight construction and optimized geometry. The balance wheel oscillates at 28,800 vibrations per hour and works with the Parachrom hairspring. This blue niobium-zirconium alloy provides superior magnetic resistance and stays up to 10 times more precise during shocks.

Rolex’s automatic movements utilize kinetic energy from your wrist movements, unlike manual watches. The semi-circular rotor’s free pivot at its center winds the mainspring with each motion. Rolex patented its perpetual rotor in 1931, which allows bi-directional winding through the distinctive red reversing wheels introduced in 1959. A clever clutch system protects the delicate internal mechanism by preventing overwinding.

Synthetic rubies help curb friction at high-contact points in Rolex movements, rating 9 on the Mohs hardness scale. These jewels serve as bearings that extend the movement’s lifespan and improve accuracy. Standard “fully jeweled” watches contain 17 rubies. Modern Rolex chronographs like the Daytona showcase 44 jewels, showing their mechanical complexity and precision engineering.

Four iconic calibers stand out in Rolex’s mechanical lineup. Each represents a crucial step in the brand’s watchmaking development.

The Caliber 3135 became Rolex’s main movement after its launch in 1988. This reliable 28.5mm diameter, 6mm tall automatic movement runs at 28,800 vibrations per hour. You’ll find it in many models from the classic Datejust to the professional Submariner Date. Its durability comes from a larger size that fits more components. The movement has 31 jewels and changes date instantly at midnight. It features the Microstella adjustment system with four screws placed at equal points along the balance wheel to regulate timekeeping precision. The bidirectional Perpetual winding system works quietly and winds the mainspring effectively in any rotation direction.

Rolex launched the Caliber 3235 in 2015 with over 90% new components and 14 patents. While keeping the same 28.5mm diameter as the 3135, this new version gives you a 70-hour power reserve instead of 48 hours. The patented Chronergy escapement makes this possible by boosting energy efficiency 15% through a pierced, lighter escape wheel that cuts down inertia. The thinner barrel walls fit a longer mainspring without making the movement bigger. The 3235 has taken over from the 3135 in many watches, including the Datejust 41, Sea-Dweller 43, and Yacht-Master models.

The Caliber 4130, which took five years to develop, powers the Cosmograph Daytona since 2000. This self-winding chronograph movement uses a vertical clutch mechanism that works like a car’s manual transmission. It starts and stops precisely without the “stutter” you see in lateral clutch chronographs. The 4130 uses 20% fewer parts than its predecessor but offers a 72-hour power reserve. The innovative UV-LIGA wheel’s finely-skeletonized teeth work like cantilevered springs, giving full surface contact during chronograph operation. The movement’s streamlined counter systems created room for a bigger mainspring barrel.

The Caliber 9001, which powers the Sky-Dweller since 2012, stands as Rolex’s most complex movement. The newer Caliber 9002 version includes the Chronergy escapement to improve energy efficiency. This mechanism runs the watch’s dual time zone display on a rotating, off-centered 24-hour disk. The SAROS annual calendar system cleverly uses hour indices as month indicators. Small openings above each hour marker show the month—one o’clock means January, two o’clock February, and so on. The caliber runs for 72 hours and needs date adjustment just once a year when February ends.

Rolex watches are renowned for their precision. Their exceptional accuracy comes from state-of-the-art engineering marvels hidden inside each timepiece. These components work in perfect harmony to deliver the performance that makes Rolex legendary.

Rolex revolutionized movement technology in 2000 with the Parachrom hairspring. This tiny component, just one centimeter in diameter, uses an exclusive alloy of niobium, zirconium, and oxygen. The results are impressive – complete immunity to magnetic fields, excellent temperature stability, and shock resistance ten times better than traditional hairsprings. Rolex added a surface treatment in 2005 that boosted long-term stability and created the hairspring’s signature blue color. This blue shade carries historical significance because watchmakers reserved blued hairsprings for their finest timepieces.

The Paraflex shock absorber protects the balance wheel’s delicate pivots. This patented system delivers 50% better shock protection than conventional methods. The design features a unique spring geometry that stays firmly in place regardless of wear conditions. Its symmetrical design allows placement from any angle without compromising performance. The system makes assembly and maintenance easier, proving its value beyond just durability improvements.

Rolex created another breakthrough with the Syloxi hairspring, crafted from silicon and silicon oxide composite. This component overcomes traditional limitations through specially optimized coils that vary in pitch and thickness. The design compensates for gravity’s effects no matter the watch’s position. A flexible collet attaches the hairspring without glue, which keeps the inner end perfectly centered and perpendicular. The outer section ends in a reinforced arc with two-point bridge attachment.

Rolex took the Swiss lever escapement to new heights in 2015 with the Chronergy escapement. Their research led to redesigned pallet fork and escape wheel components using nickel-phosphorus alloy that resists magnetism. The escape wheel’s unique cut-out design reduces weight and inertia. These changes boost efficiency by 15% without sacrificing reliability. Modern Rolex watches get their impressive power reserves from this technology, which started in calibers 3235 and 3255 before expanding to caliber 3285 in 2018.

Rolex watch movements go through two rigorous testing phases that guarantee exceptional precision. Each timepiece must earn official certification and pass even tougher in-house standards before reaching your wrist.

Rolex submits all movements to Switzerland’s independent testing authority (COSC) for certification. Uncased movements undergo 15 days of testing in five positions at three different temperatures (8°, 23°, and 38°C). The movements face seven elimination criteria with daily checks. Movements must stay accurate within -4/+6 seconds per day to earn certification. This level of precision stands out as only about 3% of Swiss watch production achieves this certification.

All the same, Rolex takes it further. After COSC certification, the company applies its own Superlative Chronometer standards that demand twice the precision at -2/+2 seconds per day after casing. This is a big deal as it means that the standards exceed typical measures and reflect ground wearing conditions.

Standard testing doesn’t meet Rolex’s expectations, so the brand created its own testing methods. The company checks precision, waterproofness, self-winding capacity, and power reserve. These complete evaluations happen at Superlative Control, Rolex’s in-house testing unit, where requirements are especially tough.

Each timepiece goes through detailed checks at every manufacturing stage before leaving the facility. This strict approach will give extraordinary performance in all functions. Rolex’s confidence in their process led them to extend their international warranty from two to five years, marked by a distinctive green seal.

The Caliber 3230, launched in 2020, showcases Rolex’s assembly mastery. We designed this caliber to deliver approximately 70 hours of power reserve through two major breakthroughs. The barrel uses thinner walls to fit a longer mainspring, while the Chronergy escapement improves energy efficiency by 15%.

The assembly process includes the patented blue Parachrom hairspring, made from a paramagnetic alloy that makes it 10 times more precise during shocks. On top of that, it uses Paraflex shock absorbers that boost shock resistance. The movement then undergoes all standard testing protocols to earn its Superlative Chronometer certification.

Learning about the intricate world of Rolex movements reveals the brilliant engineering behind each timepiece. These mechanical marvels mean much more than status symbols. They showcase horological excellence refined through generations.

Rolex movements stand out well beyond their COSC certification. Their proprietary breakthroughs like the paramagnetic Parachrom hairspring and energy-efficient Chronergy escapement expand watchmaking possibilities while staying reliable. The progress from the workhorse Caliber 3135 to the sophisticated Caliber 9001 shows Rolex’s steadfast dedication to refinement rather than complete redesign.

A quick glance at your Rolex reveals more than time. Behind that elegant exterior ticks a precision instrument with hundreds of components working harmoniously. Each part has purpose – from tiny jewels reducing friction to innovative shock absorbers protecting delicate components. These elements play a significant role in keeping perfect time.

Many collectors focus on dial variants and case materials. Your knowledge of these hidden mechanical achievements brings a deeper connection to your timepiece. Rolex movements earn their reputation through intense testing that goes way beyond industry standards. They double the precision requirements of traditional chronometer certification.

This dedication to excellence explains why vintage Rolex watches still run flawlessly decades later. The brand’s uncompromising quality standards turn these timepieces into family heirlooms. They tell more than time – they share stories of engineering mastery that few can match but many admire.

While there’s no single definitive way to authenticate a Rolex movement, genuine Rolex watches typically have a smooth, continuous seconds hand motion. The overall precision, finishing quality, and presence of proprietary components like the free-sprung balance are good indicators. However, it’s best to have a reputable dealer authenticate the watch if you’re unsure.

Rolex has primarily used three types of movements throughout its history: manual wind movements, quartz movements, and automatic self-winding movements. Today, most Rolex watches feature highly sophisticated automatic movements with various proprietary innovations.

The Caliber 3135 is often referred to as Rolex’s “workhorse” movement. Introduced in 1988, it has powered more popular Rolex models than any other mechanism. Known for its reliability and 48-hour power reserve, it features 31 jewels and operates at 28,800 vibrations per hour.

Rolex subjects all movements to rigorous testing, including COSC certification and their own Superlative Chronometer standards. They use innovations like the Parachrom hairspring for magnetic resistance, Paraflex shock absorbers for durability, and the Chronergy escapement for energy efficiency. Each movement undergoes extensive in-house testing beyond industry standards.

The Chronergy escapement is Rolex’s enhanced version of the Swiss lever escapement, introduced in 2015. It features a redesigned, lighter escape wheel made from nickel-phosphorus alloy. This innovation improves energy efficiency by 15% while maintaining reliability, contributing to the impressive power reserves in modern Rolex timepieces.

The Rolex Oysterdate Precision 6694 offers the perfect starting point to step into the exciting world of Rolex. This timepiece carries a rich heritage dating

Rare Rolex dials have become the ultimate prize for serious watch collectors looking for that perfect addition to their collection. Nothing shows true expertise in

The Grand Seiko vs Rolex debate pops up naturally for anyone looking at luxury timepieces in the $5K-$10K range. These prestigious brands showcase different paths